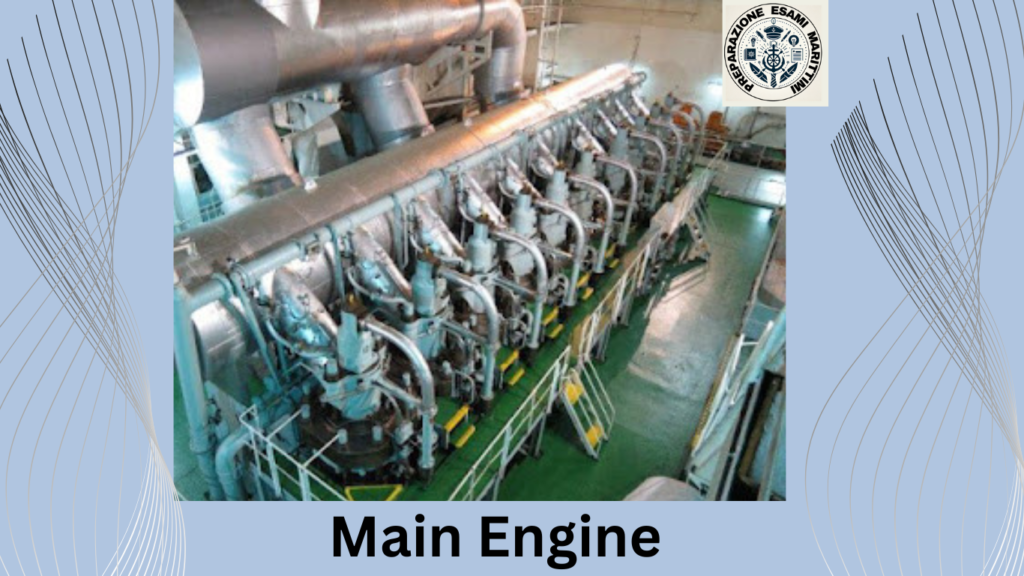

Main Engine Preparation and Checks

Marine engines are among the largest and most complex machinery systems globally. Proper preparation and systematic checks are crucial to ensure safe, efficient, and smooth operations. This guide outlines the essential steps to prepare, inspect, and operate a ship’s main engine before starting, during operation, and before stopping.

📖 References & Further Reading:

✅ Key Systems to Check Before Starting the Main Engine

Before starting the main engine, thorough inspections of these five critical systems must be performed:

🔹 Air System

🔹 Fuel System

🔹 Water System

🔹 Lube Oil System

🔹 Safety System

🔍 Comprehensive Pre-Start Engine Checks

🌬️ Air System Checks

✔️ Check air compressor oil levels and inspect for water contamination.

✔️ Use only one air bottle, keeping the other on standby for emergencies.

✔️ Ensure Main Air Bottle pressure is optimal and Main Air Compressors are operational.

✔️ Drain water from the control air system at the receiver.

✔️ Confirm that the spring air is open for the exhaust valve.

✔️ Open spring air before activating hydraulic oil to prevent excessive valve opening.

⛽ Fuel System Checks

✔️ Activate supply trace heating for fuel pipes.

✔️ Maintain fuel oil temperature between 130-140°C at the injection point.

✔️ Set the viscosity controller to auto mode when the required level is reached.

✔️ Drain water from service and settling tanks.

✔️ Ensure the governor linkage operates smoothly and check the governor’s lube oil level.

💧 Water System Checks

✔️ Maintain cooling water temperature at 50°C when the engine is stopped.

✔️ Check the jacket cooling water expansion tank level.

✔️ Verify the automatic vent valve functionality.

✔️ Isolate the jacket water preheater when the engine reaches higher RPM.

🛢️ Lube Oil System Checks

✔️ Inspect oil levels in the main engine sump, cylinder oil daily tank, and camshaft lube oil tank.

✔️ Check the turbocharger’s oil level using a sight glass.

✔️ Turn the engine with the turning gear and check auto cylinder oil lubrication.

✔️ Ensure lube oil cooler sea water valves are functional.

🚀 Step-by-Step Process to Start the Main Engine

1️⃣ Disengage the turning gear.

2️⃣ Start the main lube oil and camshaft pump while monitoring pressure and temperature.

3️⃣ Start the Jacket Cooling Water (JCW) pump and observe pressure levels.

4️⃣ Open the main air valve and air distributor.

5️⃣ Check oil flow through the sight glasses in the piston cooling outlet and turbocharger.

6️⃣ Test the engine on Ahead and Astern directions using air.

7️⃣ Start the fuel oil pump and auxiliary blowers.

8️⃣ Follow bridge telegraph orders and initiate the engine on air and fuel.

9️⃣ Inspect cylinder indicator cocks for water accumulation.

🔟 Check fuel injectors, air starting valve leakage, and exhaust valve operation.

🛑 Stopping the Main Engine: Crucial Preparations

When approaching the port, follow these key steps:

⚡ If switching to diesel fuel, initiate the changeover process one hour before maneuvering.

⚡ Start an additional generator for backup power.

⚡ Ensure the auxiliary blower switch is set to auto mode.

⚡ Drain the air bottle and control air receiver.

⚡ Stop the fresh water generator one hour before arrival.

⚡ Engage the turning gear 15-30 minutes after stopping the engine.

⚡ Shut down non-essential equipment.

🔄 Efficient Fuel Type Transition Procedures

⚡ Switching from Heavy Fuel Oil (HFO) to Diesel Oil (DO):

✔️ Maintain diesel oil temperature at 50°C.

✔️ Shut off steam to fuel oil heaters and steam tracing lines.

✔️ Reduce engine load to 75% Maximum Continuous Rating (MCR).

✔️ Gradually transition to diesel oil once HFO temperature drops 25°C above DO temperature.

🔥 Switching from Diesel Oil to Heavy Fuel Oil:

✔️ Ensure the HFO service tank temperature is optimal.

✔️ Gradually heat diesel oil to 70-80°C before switching.

✔️ Slowly introduce HFO into the system while closing the diesel oil valve.

🌊 Final Thoughts

A well-maintained and thoroughly checked main engine is key to smooth sailing and preventing mechanical failures. Following these systematic checks and procedures enhances engine performance, extends lifespan, and ensures compliance with safety standards.

📌 For more expert insights on marine engine maintenance, stay tuned to our blog! 🚢⚙️